(2) Well Formation

1.

=> n-well Mask

1) Photolithography

- HMDS

- PR coating

- Soft Bake

- Align and exposure

- PEB

- Develop

- Hard nake

2) Ion implantation

- Phosphorus, 120keV, 6x10^12cm^-2

3) PR strip

- Oxygen plasma ashing

- H2SO4 strip

2.

=> p-well Mask

1) Photolithography

- HMDS

- PR coating

- Soft Bake

- Align and exposure

- PEB

- Develop

- Hard nake

2) Ion implantation

- Boron, 80keV, 6x10^12cm^-2

3) PR strip

- Oxygen plasma ashing

- H2SO4 strip

3.

1) Pre-furnace cleaning

- SPM, SC1, SC2

- 고온 열처리하기 전에 시행

(∵ clenaing을 진행하지 않으면, 여러 오염 물질들이 확산 가능 -> 전기적 특성에 영향)

2) Well drive-in

- 1000도, 10h

- 목적) dopant diffusion 발생

3) SiO2 strip

4) Pre-furnace cleaning

- SPM, SC1, SC2

5) Buffer oxide re-grow

- thermal oxidation

- 목적) channeling 방지

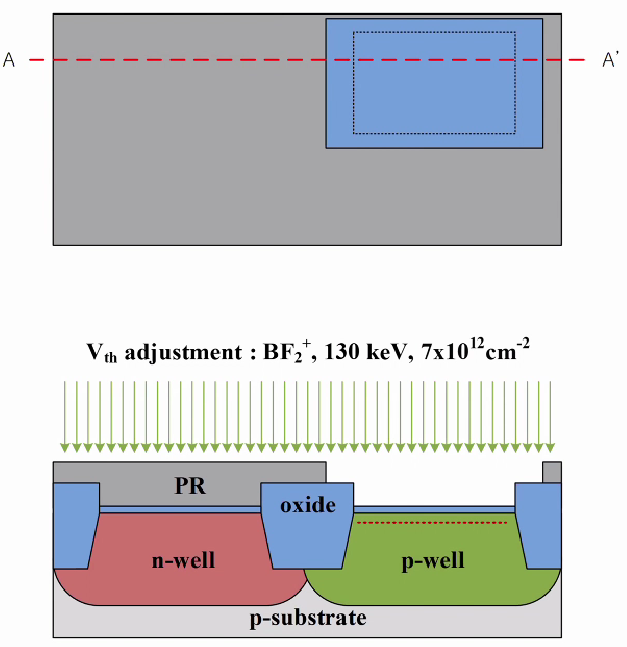

(2-1) Threshold Voltage Adjustment

=> Vt가 낮을 때, channel 쪽에 doping을 하는 과정

=> pvt Mask

=> nvt mask

1) Photolithography

2) Ion implantation

3) PR strip

'반도체 공정' 카테고리의 다른 글

| CMOS process flow_LDD implantation/HDD implantation (0) | 2024.05.23 |

|---|---|

| CMOS process flow_gate stack deposition and patterning (0) | 2024.05.22 |

| CMOS process flow_isolation (0) | 2024.05.19 |

| CMOS Process Flow (0) | 2024.05.18 |

| Cleaning (0) | 2024.03.25 |